Industry news

Two major modification directions of PPS

Release time:2019/4/15 9:17:00

Author:admin

Clicks:

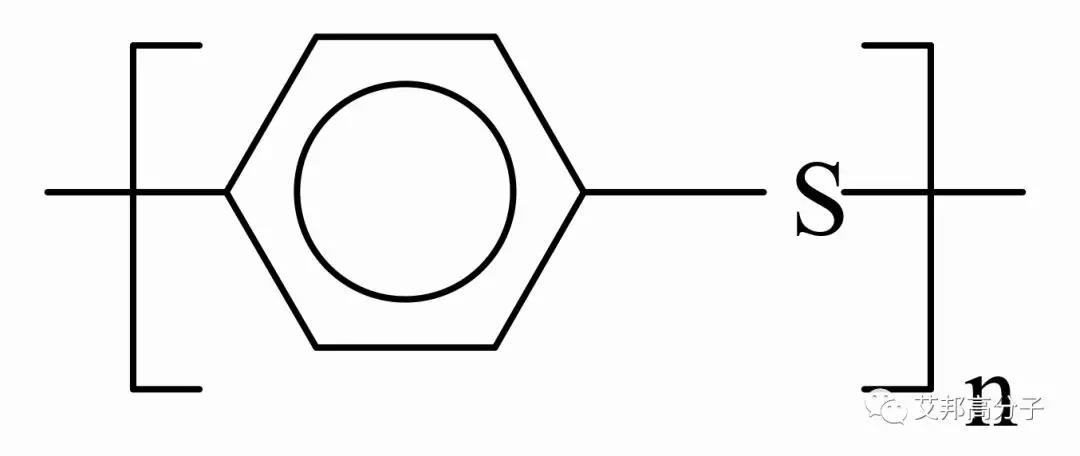

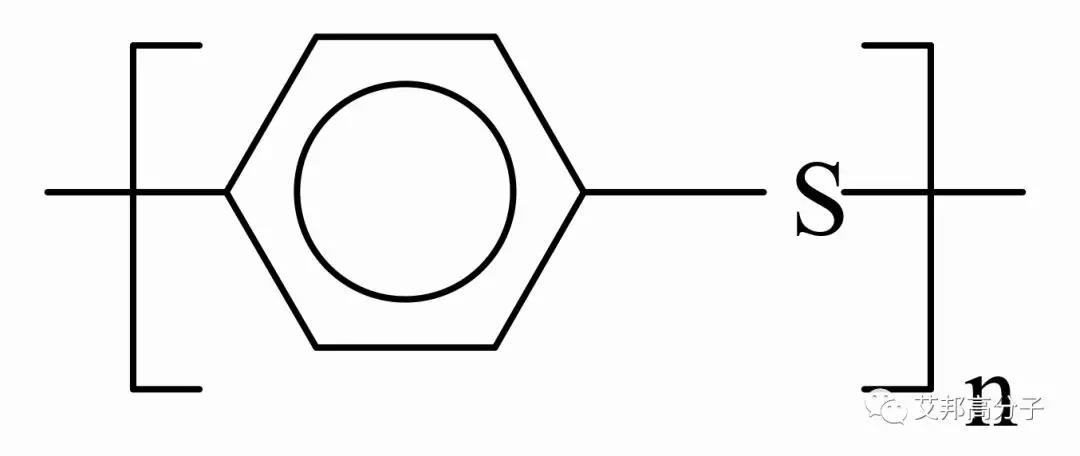

Polyphenylene sulfide (PPS) is a linear polymer compound composed of benzene rings and sulfur atoms alternately arranged. Because the rigid structure of the benzene rings is linked by soft sulfide bonds, it has excellent heat resistance, flame retardance, medium resistance and good affinity with other inorganic fillers.

Figure PPS structure

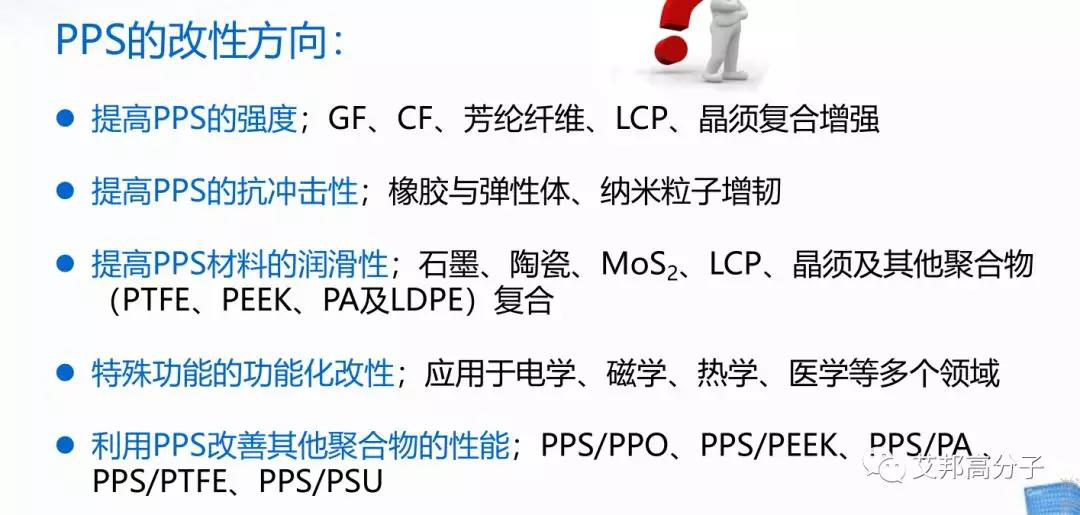

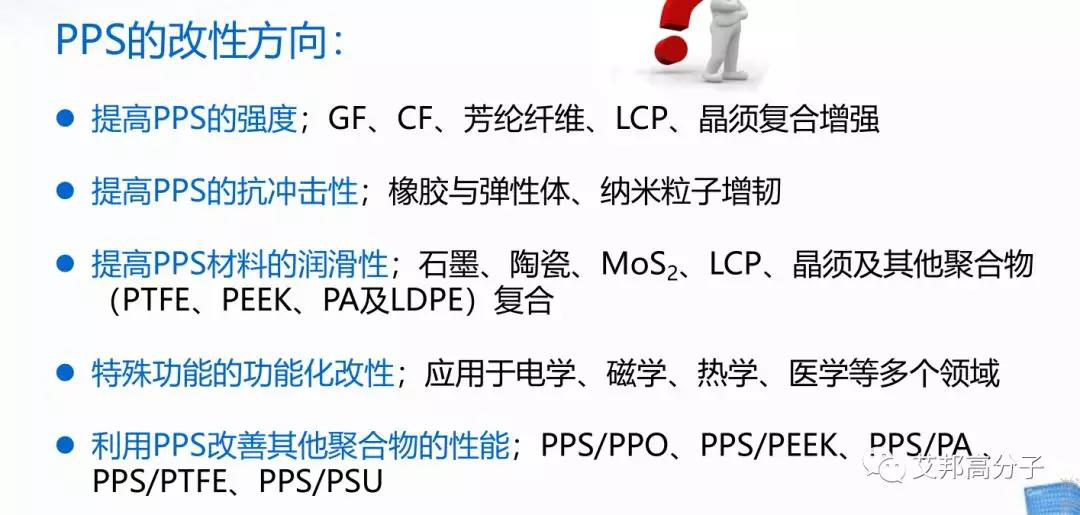

Since the successful development of PPS, people have carried out more modification and development work on it, and many modified varieties have emerged. According to the chemical / physical modification means, it can be mainly divided into two types: structure modified PPS and blending modified PPS, of which blending modified PPS can be further divided into filling modified PPS and PPS alloy.

Fig. PPS modification direction

Among them, filling modified PPS is the most common. Glass fiber, carbon fiber and other inorganic fillers are often used to enhance filling modification, so that it can further improve physical and mechanical properties while maintaining heat resistance, flame retardancy and medium resistance, and give some special properties, such as conductivity, heat dissipation, magnetism and so on.

The material that is also modified by the blending principle and blended with multi-component resin and PPS is called PPS alloy. The varieties are PPS / PPO, PPS / PA66, PPS / LCP, etc. alloying other low-cost resins with PPS with relatively high cost can effectively reduce the cost pressure, take advantage of the strengths to compensate for the weaknesses, and overcome the shortcomings of PPS resin itself.

It is relatively simple to modify PPS by physical modification, so there are many PPS modification enterprises in China, such as Pulit, eurida, Suzhou napan, sainji and so on.

Structural modification is to introduce other groups into the chain to improve the performance of the resin while maintaining its main chain structure. Such as fluidity, crystallinity, toughness and so on, this modification is completed when synthesizing resins, so it is generally modified by PPS polymerization plants. This is done more abroad, and only XinHeCheng has developed a high crystallinity specification PPS resin for the structural modification of PPS in China.

Therefore, only two aspects of fiber modified PPS and PPS alloy will be further elaborated and applied examples will be given below.

1、 Filling modified PPS

There are many purposes of filling modification, such as strengthening, toughening, heat conduction, wear resistance, antistatic, low chlorination, etc., so there are also many kinds of fillers that can be added. The most common reinforced filling modified PPS is glass fiber reinforcement, in addition to glass fiber mineral, carbon fiber, aramid fiber and other reinforced filling methods.

Due to the existence of a large number of benzene rings on the main chain of PPS, the rigidity of the material is increased, so that the unmodified PPS material is relatively brittle, has poor mechanical properties, and has a relatively low heat resistance temperature, only 110 ℃, which limits its application. Therefore, using glass fiber or inorganic mineral filler to modify PPS can improve its mechanical properties and heat resistance, and the thermal deformation temperature can reach 260 ℃.

2、 PPS alloy

Alloying is to blend PPS with other polymers in an appropriate proportion to obtain PPS alloy materials whose properties cannot be reached by PPS. This method is an important way to realize high performance, refinement and functionalization of PPS and develop new varieties. In the alloy system, not only the properties of each component are complementary, but also they can be designed according to the actual needs to obtain new materials with excellent properties.

For example, due to the poor impact resistance of polyphenylene sulfide, blending PBT resin with polyphenylene sulfide can not only maintain the original excellent performance of polyphenylene sulfide, but also achieve the purpose of toughening. Polyphenylene sulfide / PTFE alloy is widely used in machinery, automobile, aerospace and military fields because of its high wear resistance and self-lubricating characteristics.

Figure PPS structure

Since the successful development of PPS, people have carried out more modification and development work on it, and many modified varieties have emerged. According to the chemical / physical modification means, it can be mainly divided into two types: structure modified PPS and blending modified PPS, of which blending modified PPS can be further divided into filling modified PPS and PPS alloy.

Fig. PPS modification direction

Among them, filling modified PPS is the most common. Glass fiber, carbon fiber and other inorganic fillers are often used to enhance filling modification, so that it can further improve physical and mechanical properties while maintaining heat resistance, flame retardancy and medium resistance, and give some special properties, such as conductivity, heat dissipation, magnetism and so on.

The material that is also modified by the blending principle and blended with multi-component resin and PPS is called PPS alloy. The varieties are PPS / PPO, PPS / PA66, PPS / LCP, etc. alloying other low-cost resins with PPS with relatively high cost can effectively reduce the cost pressure, take advantage of the strengths to compensate for the weaknesses, and overcome the shortcomings of PPS resin itself.

It is relatively simple to modify PPS by physical modification, so there are many PPS modification enterprises in China, such as Pulit, eurida, Suzhou napan, sainji and so on.

Structural modification is to introduce other groups into the chain to improve the performance of the resin while maintaining its main chain structure. Such as fluidity, crystallinity, toughness and so on, this modification is completed when synthesizing resins, so it is generally modified by PPS polymerization plants. This is done more abroad, and only XinHeCheng has developed a high crystallinity specification PPS resin for the structural modification of PPS in China.

Therefore, only two aspects of fiber modified PPS and PPS alloy will be further elaborated and applied examples will be given below.

1、 Filling modified PPS

There are many purposes of filling modification, such as strengthening, toughening, heat conduction, wear resistance, antistatic, low chlorination, etc., so there are also many kinds of fillers that can be added. The most common reinforced filling modified PPS is glass fiber reinforcement, in addition to glass fiber mineral, carbon fiber, aramid fiber and other reinforced filling methods.

Due to the existence of a large number of benzene rings on the main chain of PPS, the rigidity of the material is increased, so that the unmodified PPS material is relatively brittle, has poor mechanical properties, and has a relatively low heat resistance temperature, only 110 ℃, which limits its application. Therefore, using glass fiber or inorganic mineral filler to modify PPS can improve its mechanical properties and heat resistance, and the thermal deformation temperature can reach 260 ℃.

2、 PPS alloy

Alloying is to blend PPS with other polymers in an appropriate proportion to obtain PPS alloy materials whose properties cannot be reached by PPS. This method is an important way to realize high performance, refinement and functionalization of PPS and develop new varieties. In the alloy system, not only the properties of each component are complementary, but also they can be designed according to the actual needs to obtain new materials with excellent properties.

For example, due to the poor impact resistance of polyphenylene sulfide, blending PBT resin with polyphenylene sulfide can not only maintain the original excellent performance of polyphenylene sulfide, but also achieve the purpose of toughening. Polyphenylene sulfide / PTFE alloy is widely used in machinery, automobile, aerospace and military fields because of its high wear resistance and self-lubricating characteristics.